© Greenstick Enerygy Limited 2019 website design by Geoffrey Miller : www.flamboroughmanor.co.uk

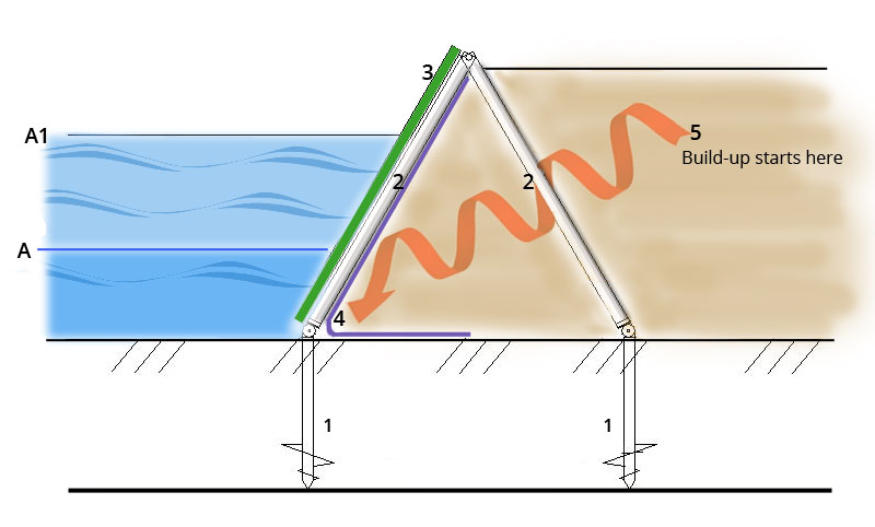

Where 1=Greenstick piles; 2=Pivoting adjustable shafts; 3=Panel; 4=Permeable or non-

permeable membrane; 5=Reclaimed pulp. A=Starting water level; A-A1=Tidal range

Greenstick Wall Technology

The Greenstick can be used with fibre reinforced plastic (FRP) panels to create a retaining wall, offering many uses. The

image, below, demonstrates how this technology can be used in the creation of an artificial territory.

The Greenstick wall construction phases are as follows:

1.

Vertical screw piling of Greensticks as per stakeout axes

2.

Pivoting adjustable shaft remains locked until the FRP walls are inserted into keyway to form wall

3.

Greenstick joints unlocked, FRP panel wall positioned to required angle & made firm by connecting to the supporting

row of Greensticks to form a secure structure

4.

Permeable or non-permeable membrane set into position

5.

Dredged soil transferred over the Greenstick wall to fill the void

Greenstick piles are capable of holding high vertical and horizontal loads. The slope of the wall reduces the active

earth pressure on the FRP panel, reducing the horizontal force and keeping the Greenstick in place.

The Greensticks and the FRP panels can serve as a permanent structure or have the added benefit of being fully

removable and re-utilised elsewhere if required.

The benefits of using Fibre Reinforced Plastic (FRP) panels

FRP has a number of advantages compared with materials traditionally used in hydraulic engineering, for example:

•

Unlike concrete, low water absorption makes FRP resistant to freezing and thawing

•

FRP tensile strength is higher than that of steel

•

FRP can be manufactured with significantly higher abrasion resistance than that of concrete or steel

•

Usage of lightweight FRP is likely to reduce construction time and cost

•

FRP, not being subject to chemical or electrochemical corrosion, is suitable for marine hydraulic structures

and is cheaper than concrete or steel

•

FRP has the thermal conductivity of wood, preventing ice from forming on the surface

•

FRP can be manufactured in any colour making it more aesthetically pleasing than other materials